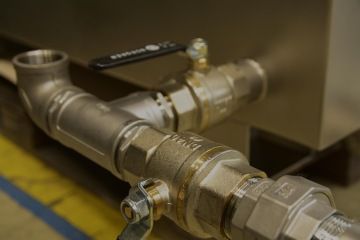

PROCESSING OF GALVANISED AND STAINLESS STEEL, ALUMINIUM AND OTHER METALS

The scope of the services provided begins with the preparation of the technical documents and a suggestion of the specific product solution, including the related calculations. In case of specific products, external organisations are involved to provide relevant certificates. We perform laser cutting of sheet metal, punch cutting of sheet metal, plasma cutting, bending and rolling of sheet metal, welding, surface treatment, assembling and 3D measurements.